In pioneering industries such as aerospace, new energy transportation, and high-end equipment, the application of composite materials is continuously expanding in both depth and breadth. The manufacturing capabilities in this field have become a key indicator of a global industrial competitiveness.

Leading enterprises in this sector are no longer facing mere cutting tasks; rather, they are challenged with transforming high-value, high-performance raw materials into defect-free precision components through ultra-stable, efficient, and intelligent processes.IECHO recognizes that what customers need is not just a high-performance machine, but a strategic partner capable of deeply engaging with their process chain and providing continuous innovation support. The IECHO SK2 High-Precision, Multi-Industry Flexible Material Cutting System embodies this partnership.

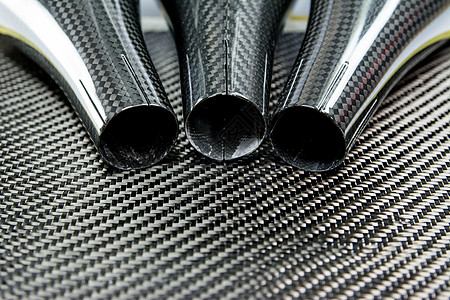

Building a Dedicated Productivity System for Composites

What value can the IECHO SK2 bring to the composites industry?

Precision Motion Control: The SK2 linear motor drive ensures exceptional trajectory accuracy and dynamic stability, guaranteeing perfect fiber orientation and edge consistency when cutting carbon fiber fabrics and complex sandwich structures. This precision is essential for lightweight, high-strength components where design intent cannot be compromised.

Intelligent Optimization: Advanced vision alignment and smart nesting software allow the SK2 to automatically identify material features and optimize layouts, reducing waste even with costly composite materials.

Flexible Processing: With rapid tool changes, the SK2 handles a wide variety of composites; from aramid honeycomb cores and foam sandwiches to specialty prepregs, offering one-stop flexible processing that supports both R&D and production.

Comprehensive Service Support: IECHO Commitment and Value

Professional Implementation and Fast Start-Up

From the moment you place your order, our team ensures smooth production integration, from line planning and installation to full commissioning, so your SK2 is quickly operational.

Training and Capability Building

Multi-level training covers equipment operation, maintenance, advanced processes, and troubleshooting. Your team will not only operate the machine efficiently but gain a deep understanding of the processes, building internal expertise and production autonomy.

Responsive Technical Support and Preventive Maintenance

Remote diagnostics, hotline support, and on-site service minimize downtime and ensure continuous production through proactive preventive maintenance and rapid response.

Continuous Process Improvement and Upgrades

As materials and market demands evolve, our service team provides ongoing process optimization, functional upgrades, and software updates; keeping your SK2 ahead of production challenges and protecting your long-term investment.

By choosing IECHO, you gain not just a top-tier cutting system, but a long-term service partner dedicated to your production success. We are committed to becoming the most reliable link in your supply chain through dependable, professional, and timely support.

Post time: Jan-12-2026