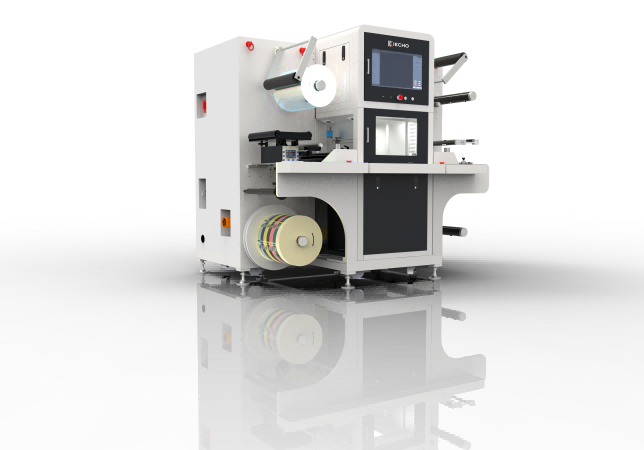

In the label printing industry, where efficiency and flexibility are increasingly demanded, IECHO has launched the newly upgraded LCT2 Laser Die-Cutting Machine. With a design emphasizing high integration, automation, and intelligence, the LCT2 provides global customers with an efficient and precise digital die-cutting solution. The machine combines intelligent die-cutting, lamination, slitting, waste removal, and sheet separation functions in one system, significantly improving production efficiency, reducing labor dependence, and particularly meeting the needs of flexible, small- to medium-batch production.

Die-Free Production, Simplified Workflow, Rapid Response

The IECHO LCT2 enables truly “die-free” production. Users simply import electronic files, and the machine enters the cutting process directly, eliminating the traditional die-making steps. This innovation not only shortens setup time but also significantly reduces production costs, making it ideal for prototyping and fast-turnaround orders, helping your business to gain a competitive edge in a rapidly changing market.

Smart Feeding and Precision Control for High-Speed Stable Operation

Featured with an intelligent feeding system and a high-precision tension control mechanism, the LCT2 machine supports stable material feeding for rolls up to 700 mm in diameter and 390 mm in width. With an ultrasonic correction system, it continuously monitors and actively adjusts the material position, effectively preventing misalignment, ensuring every cut starts perfectly and preventing waste.

Automatic Job Switching via QR Code for Diversified Production

The LCT2 comes with advanced QR code “Scan to Switch” function. QR codes on material rolls instruct the machine to automatically retrieve the corresponding cutting plan. Even when a roll contains hundreds of different designs, continuous uninterrupted production is possible. This system is especially suited for personalized and small-format orders, with a minimum cut length of just 100 mm and a maximum production speed of 20 m/min, achieving an ideal balance between flexible customization and high output.

With QR cod “Scan to Switch” function, the LCT2 can automatically load the right cutting plan for each roll. Even rolls containing hundreds of different designs can be processed continuously without interruption. Ideal for personalized or small-format orders, the system supports minimum cut lengths of just 100 mm and speeds up to 20 m/min; striking the perfect balance between customization and high output.

High-Performance Laser Cutting: Efficiency Meets Quality

At the core of the machine, the laser cutting system has an effective cutting width of 350 mm and a laser head flight speed of up to 5 m/s, achieving high-speed cutting while maintaining smooth edges and consistent quality. Additionally, the machine integrates a missing-mark detection system for real-time quality control. The waste collection and material retrieval system forms a complete closed loop, with an optional sheet cutter to support roll-to-sheet output.

A Reliable Partner for Digital Transformation

The IECHO LCT2 is not just a high-performance machine; it is a key partner for enterprises seeking intelligent manufacturing upgrades. By reducing die costs, improving intelligent operation, and ensuring consistently precise processing, the LCT2 aims to create sustainable, long-term value for its customers.

For more information on the LCT2 laser die-cutting machine’s technical specifications or application cases, please feel free to contact the IECHO team. We are dedicated to supporting you every step of the way.

Post time: Dec-01-2025