In today’s fast-evolving digital printing landscape, short-run, customized, and fast-turnaround production has become an unstoppable trend in the label industry. Orders are getting smaller, deadlines shorter, and designs more diverse—creating major challenges for traditional die-cutting, such as slow job changeovers, material waste, high labor dependency, and costly plate production.

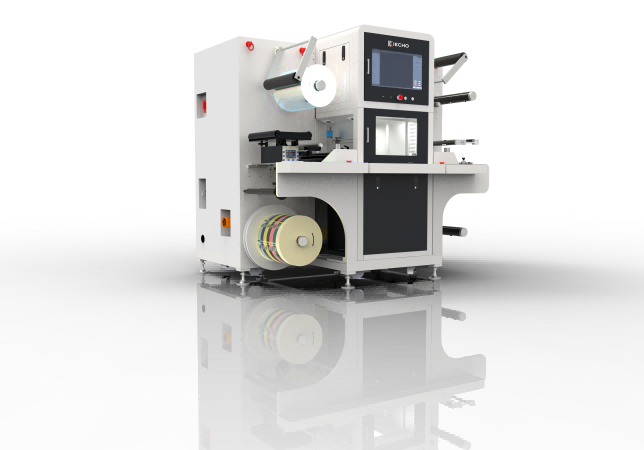

To address these issues, IECHO introduces the upgraded LCT2 Laser Die-Cutting Machine, now featuring a “Scan to Switch” system. With intelligent and automated cutting workflows, it empowers printing companies to handle small orders quickly, cut costs, and boost productivity in an increasingly competitive market.

Solving the Industries Biggest Challenges: IECHO Ultimate Solution

|

Customer Challenges |

IECHO Solutions |

| Short-run, highly customized orders | “Scan to Switch” supports layouts as short as 100 mm, easily handling ultra-small batches |

| Frequent job changeovers | Auto recognition and switch via QR code, no manual setup; change jobs in seconds |

| Rising costs and material waste | Smart path optimization maximizes material use; one operator can monitor multiple machines |

| Tight deadlines, urgent delivery needs | High-speed cutting (up to 20 m/min) + “Scan to Switch” = same-day turnaround made easy |

| Inconsistent die-cut accuracy | Real-time parameter adjustment ensures precise cutting, even with varying label sizes |

| High sampling cost and inefficiency | No die plates required, start from a single sheet, saving time and cost |

| Fierce price competition | Enhance competitiveness with advanced automation and differentiation |

| Constantly changing customer designs | Supports variable data printing and complex design adaptation |

| High reliance on skilled labor | Automation and intelligent control reduce dependency on manual operation |

Smart Job Switching: Big Results from Small Runs

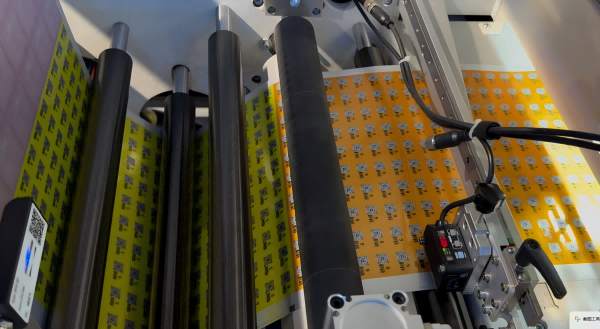

The IECHO LCT2 “Scan to Switch” system introduces an intelligent workflow where each layout is managed through its own QR code. Once scanned, the system automatically recognizes the cutting file, adjusts feeding speed, and sets the cutting path; no manual setup or tool change needed.

Even for layouts as short as 100 mm or single customized labels, LCT2 handles them with ease.

150 Cutting Files, Fully Automated

Take a 200-meter roll of coated paper as an example; with 150 different label layouts. From the first to the last label, the system automatically scans each QR code, updates cutting parameters in real time, and guarantees precise cutting every time.

No need for die plates,no blade changes, no downtime. The entire roll is completed in one seamless, automated process with zero manual intervention.

Curious how long it takes to finish the whole roll? Drop your guess in the comments!

Conclusion

The IECHO LCT2 is more than just a laser die-cutter; it’s a strategic tool for the short-run production. With its no-mold design, rapid job switching, and ability to process complex shapes, it helps printing companies build a new kind of productivity centered on speed, flexibility, and precision.

If you’re struggling with short-run efficiency or cost control, step into IECHO and experience what the LCT2 can do for your business.

IECHO LCT2 Laser Die-Cutting System: Smart Cutting Power for Every Label.

Post time: Nov-14-2025