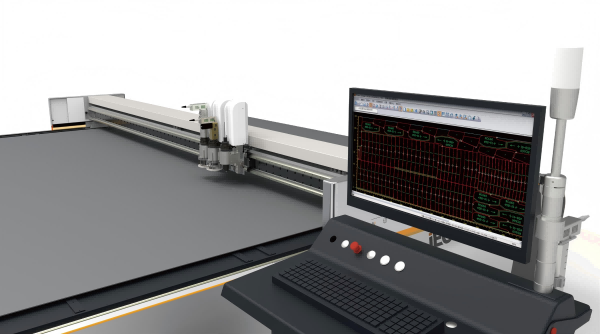

The packaging industry is undergoing a dramatic transformation: consumers want variety, products have shorter lifecycles, and e-commerce drives a surge in small-batch, custom orders. Traditional large-scale, single-product machines can’t keep up. Today’s manufacturers need equipment that can handle fast job changes, multiple cutting functions, and precise, efficient production. The IECHO SK2 multi-functional cutting system is designed as a flexible manufacturing platform to empower this transition.

Four Pillars of Flexible Productivity

1. Smart Tool Library

The SK2 automatic tool-change system allows seamless switching among UCT razor knives, PRT rotary tools, EOT oscillating knives, and POT pneumatic oscillating knives in minimal time. This means a single SK2 can replace multiple traditional single-function machines, easily handling full-range production from luxury gift boxes and corrugated displays to cardstock and foam cushioning inserts.

2. Intelligent Software

The iBrightCut and CutterServer software act as the command center for flexible production. They process large and complex graphic files quickly while enabling smart nesting and one-click process parameter matching. Operators simply select the material type, and the system automatically applies optimized knife pressure, speed, and cutting depth; significantly reducing the need for highly skilled technicians and cutting job changeover time from hours to minutes.

3.Consistent Precision

Whether it’s post-print die-cutting with registration accuracy within ±0.1 mm or seamless assembly of irregular box shapes, SK2 maintains strict long-term repeatability. Its linear motor drive and robust frame ensure that even after hundreds of thousands of cuts under continuous production, precision remains unchanged, eliminating waste caused by equipment fluctuations and safeguarding the flawless presentation of high-end packaging.

4. Expandable Automation

The SK2 was designed from day one with easy integration and future expansion in mind. It can easily integrate automatic loading/unloading robotic arms, vision alignment systems, and vacuum suction conveyor belts, creating unmanned or minimally staffed automated production units.

Built for New Business Models

E-commerce Custom Packaging:

Facing hundreds of products with different sizes and logos every day, SK2 can nest multiple orders in a single layout, automatically switching tools to complete full cuts, kiss-cuts, and waste removal. This enables customization of every sheet in a single batch while minimizing the cost of personalized packaging.

Short-Run Premium Printing:

For limited-edition promotional items or sample packaging for luxury goods and electronics, SK2 can accurately die-cut specialty finishes such as foil stamping and UV coating, producing intricate cutouts and fine folds, translating creative designs flawlessly into physical products, and enhancing product value.

POP Display Manufacturing:

To respond quickly to frequently changing retail promotions, SK2 efficiently cuts KT board, PVC foam board, honeycomb panels, and other materials, producing complex, easy-to-assemble 3D displays, helping clients bring marketing concepts to the store floor faster.

The IECHO SK2 redefines packaging productivity. No longer a heavy, single-purpose machine, it’s a flexible, smart, and efficient digital production terminal, enabling companies to capture market opportunities quickly and turn diverse customer demands into high-margin, premium products.

Post time: Jan-09-2026