In today’s industrial manufacturing environment, where demands for production efficiency and processing accuracy continue to rise, equipment performance and reliability are directly tied to a company’s core competitiveness. IECHO flagship multi-function cutting system, the SK2, sets a new benchmark for high-end industrial applications through a design that combines high reliability, outstanding performance, and exceptional value.

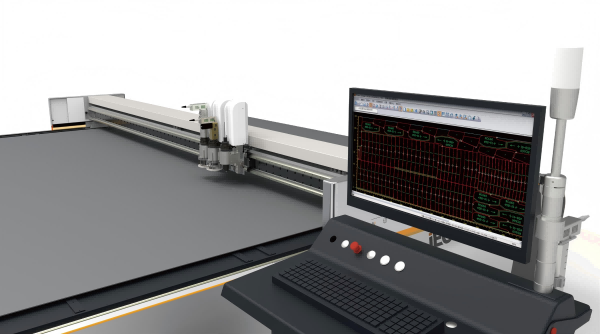

Designed for users who demand ultimate precision and high throughput, the SK2 integrates multiple advanced technologies and modular systems into a complete, stable production solution. Its core modules include an intelligent integrated safety and anti-collision system, the efficient and user-friendly iBrightCut and CutterServer control software, a high-precision conveying system, and a multi-function cutting head. Working in synergy, these components ensure a smooth and accurate workflow from design input to finished output.

Flexible Tooling for Diverse Applications

The SK2 versatility is most evident in its flexible tooling configuration. With support for fast tool switching and automatic tool changing, users can easily handle a wide range of processing requirements. Standard and optional tools include the Universal Cutting Tool (UCT), Rotary Tool (PRT), Pneumatic Oscillating Tool (POT), and Electric Oscillating Tool (EOT). Combined with the AKI high-precision optical positioning system, the SK2 delivers precise cutting results across various materials. An ergonomically designed operator stand further enhances ease of use and operator comfort.

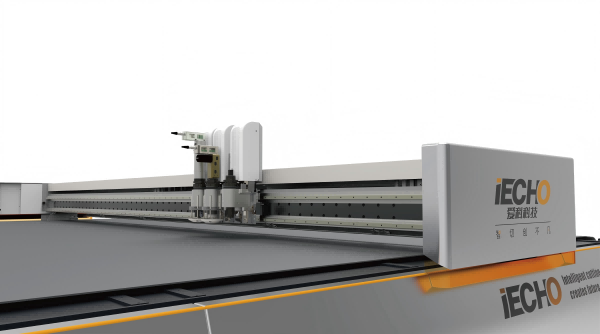

A Disruptive Drive Technology: Linear Motor System

One of the SK2 core innovations is its advanced linear motor drive system, which replaces traditional rotary motors and mechanical transmission structures. This technological shift brings several key advantages:

Higher Precision and Reliability

By eliminating mechanical backlash and wear from belts, gears, and other transmission components, the system reduces maintenance requirements while delivering long-term, stable, high positioning accuracy.

Outstanding Dynamic Performance

With rapid acceleration and deceleration response, the linear motor supports high-speed, high-dynamic operation, significantly increasing productivity.

Smoother and Quieter Operation

Low heat generation and low vibration operation greatly reduce friction-related noise, creating a more comfortable working environment.

Uncompromising Stability

Even during continuous high-speed operation, the SK2 maintains extremely high repeat positioning accuracy.

A Solid Foundation: Innovative Machine Frame Design

Stable cutting performance depends on a solid structural foundation. The SK2 features a high-strength hybrid frame made from premium carbon structural steel, offering excellent overall rigidity and dynamic load capacity. Key advantages of the frame design include:

Ease of Deployment: A modular, detachable structure simplifies transportation and on-site assembly.

Vibration Damping and Stability: Effectively absorbs and reduces vibration and jitter during high-speed cutting.

Precision and Long-Term Stability: Provides a solid foundation for cutting accuracy and long-term equipment stability, enabling reliable operation under high-speed and high-acceleration conditions, greatly improving production efficiency.

Proven Performance in Real-World Applications

In live production demonstrations, the SK2 demonstrates strong adaptability and consistency across different materials. While significantly boosting productivity, it consistently delivers excellent processing quality, achieving an optimal balance between speed and precision.

Empowering Complex Processing and Customization

Beyond efficiency and accuracy, the SK2 powerful control system supports complex graphic cutting and diverse process requirements. Cutting parameters can be adjusted and optimized based on material type and thickness. For customers with custom requirements, IECHO provides tailored system configurations to meet demanding production challenges.

Comprehensive Service Support: Your Reliable Partner

At IECHO, we believe that delivering advanced equipment is only the beginning. We are committed to being our customers long-term reliable partner, providing comprehensive service support, including:

Professional on-site installation and commissioning

Comprehensive operator and safety training

Continuous technical and process support to ensure long-term optimal performance

Through professional service, we aim to maximize customer satisfaction and equipment value while building lasting, win-win partnerships.

The IECHO SK2 multi-functional cutting system is built for high-end customers who accept no compromise and consistently uphold professional standards. It is not just a machine, it is a strategic investment toward higher precision, higher efficiency, and stronger competitiveness.

For more information or specific requirements, please feel free to contact us.

Post time: Jan-07-2026