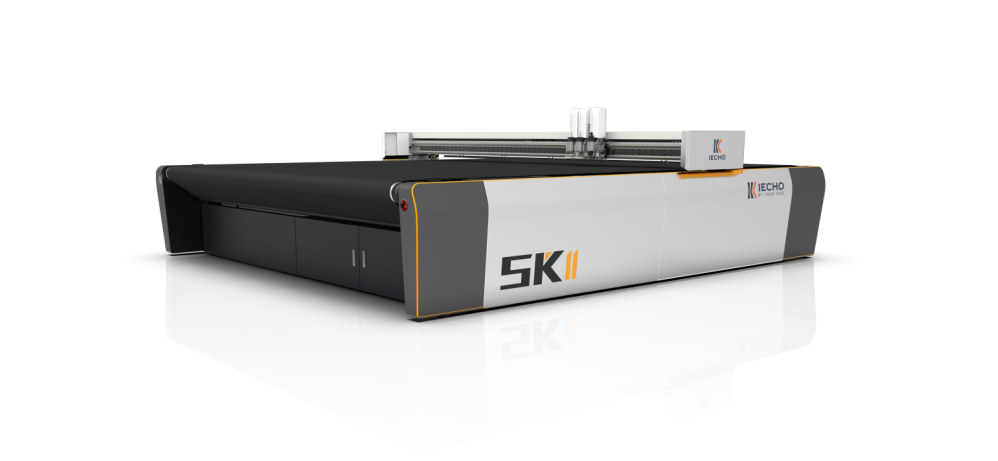

As global manufacturing continues to pursue cost reduction, efficiency improvement, and flexible production, many companies are facing common challenges: fragmented orders, rising demand for customization, tight delivery schedules, and increasing labor costs. How to process diverse materials with precision, speed, and flexibility has become key to industry upgrading. The IECHO SKII High-Precision Multi-industry Flexible Material Cutting System empowers companies to achieve automated production transformation through cutting-edge technology.

IECHO has always upheld the concept of “high precision, high speed, and multi-field compatibility,”. SKII is not just a single machine, but a comprehensive solution deeply aligned with customer pain points; designed for complex production scenarios with high order volume, strong customization, and urgent delivery requirements.

Built for Stability, Designed for People

At the core of the SKII system is high-quality carbon structural steel, machined in one piece using a large five-axis gantry milling machine to ensure a modular, high-strength steel frame. This design delivers exceptional stability, corrosion resistance, and toughness;l providing the foundation for long-term, ultra-high processing accuracy. At the same time, the system follows ergonomic design principles, offering an intuitive interface and operator-friendly layout to enhance comfort and efficiency. It’s where strong engineering meets thoughtful usability.

Intelligent Motion for Speed and Accuracy

The system adopts revolutionary linear motor drive technology, eliminating traditional mechanical transmission components such as synchronous belts and gears. This “zero-transmission” structure enables direct conversion of electrical energy into linear motion, delivering rapid response and dramatically reducing acceleration and deceleration times. It achieves operating speeds of up to 2500 mm/s while maintaining accuracy within 0.05 mm. Equipped with IECHO latest IECHOMC intelligent motion control module, the machine can dynamically adapt its motion strategy to meet processing needs across different industries.

Full-Process Automation and Unlimited Expansion

The SKII intelligent automatic nesting system covers the entire process; from sample calculation and order quotation to material procurement and cutting production. It automatically generates optimized nesting layouts and cutting paths, clearly displaying key data such as material utilization, number of pieces, and estimated time, maximizing efficiency and reducing waste. Optional upgrades include automatic feeding racks, line scanners, projection positioning devices, and robotic arms. Whether processing sheets or rolls, the system minimizes manual intervention and supports continuous, efficient automated production; ideal for both mass production and customization.

Reliable Quality, Exceptional Value

This cutting system series offers exceptional value. IECHO uses the most advanced technologies and highest-quality components to ensure unmatched flexibility, reliability, and processing quality; delivering long-term, stable returns on investment for customers.

Efficient Tool Management and Precise Nesting Cutting

The SKII system supports a flexible combination of standard cutting heads with specialized heads for punching, routing, and more, along with hundreds of optional blades to meet evolving production needs. Its integrated fiber optic automatic tool-setting system ensures precise control of cutting depth with tool-setting accuracy below 0.1 mm. Combined with IECHO fully automated camera positioning system and a high-definition CCD camera, the machine can automatically detect patterns or registration marks for accurate positioning and automatic nesting cutting. This eliminates errors caused by manual alignment or material deformation, making complex tasks simple and precise.

The launch of the IECHO SKII High-Precision Multi-Industry Flexible Material Cutting System marks a solid step forward in intelligent and automated flexible material processing. More than just a machine, it is a future-ready productivity engine designed to help manufacturers stay ahead in a competitive market.

Post time: Dec-18-2025