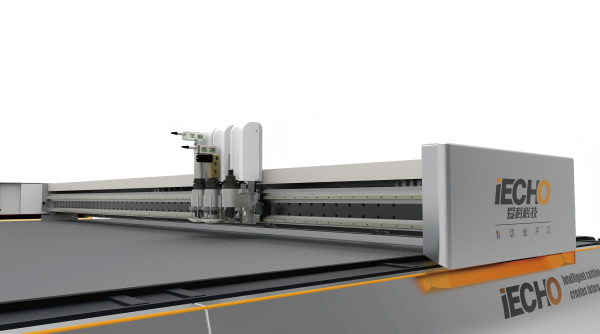

In high-end manufacturing, especially in the automotive, aerospace, and precision electronics sector, the pursuit of cutting accuracy, efficiency, and stability is relentless. Traditional mechanical transmission systems relying on belts, gears, and lead screws have gradually become bottlenecks limiting further improvements in productivity and quality. The IECHO SK2 high-precision, multi-industry flexible material cutting system marks a fundamental transformation: by eliminating all intermediate transmission mechanisms and adopting advanced linear motor direct-drive technology, it sets a new performance benchmark for industrial cutting.

Why Are Linear Motors Disruptive?

At the heart of the SK2 lies its direct-drive design philosophy:

Ultimate Precision and Near-Zero Maintenance Transmission

By completely eliminating inherent mechanical issues such as gear backlash, belt stretching and slippage, and lead screw wear, the SK2 ensures that positioning accuracy (up to ±0.05 mm) remains consistent even after tens of thousands of operating cycles. With no transmission components requiring regular replacement, the system achieves long-term, stable operation with virtually no maintenance.

Extreme Dynamic Performance

With the linear motor drive directly connected to the load, response times are extremely short, enabling very high acceleration levels (far exceeding those of traditional servo-driven systems) and instant high-speed motion. Cutting speed can be increased by over 50% compared to conventional solutions. When processing large volumes of small graphics or complex paths, non-cutting travel time is significantly reduced, resulting in a substantial boost in overall productivity.

Exceptional Stability and Ultra-Quiet Operation

The non-contact electromagnetic drive fundamentally eliminates vibration and heat caused by mechanical friction. Even during high-speed, full-load operation, machine temperature rise is minimal and thermal deformation is negligible, ensuring consistent precision during long production runs. At the same time, operating noise can be reduced to below 65 dB, greatly improving the working environment for operators.

How Does Technology Translate into Productivity?

Automotive Interior Applications

For increasingly complex cutting tasks involving PU, microfiber, and composite materials used in seats and door panels, the SK2 linear motor drive executes high-speed, high-precision cutting of intricate curves with ease. Its rapid acceleration and deceleration ensure no overshoot or rounded corners at turns, delivering smooth, clean edges without laser scorching or mechanical pressure marks, meeting luxury automotive brands stringent“zero-defect”standards.

Composite Material Processing

In applications such as carbon fiber prepregs and fiberglass fabrics, the high cost of materials demands minimal waste. Thanks to its unrivaled motion control precision and stability, the SK2 enables tight nesting layouts with extremely small gaps between cutting paths, significantly improving material utilization. Precise control of oscillating tools also ensures perfect cuts without damaging the underlying release paper.

High-End Packaging and Display Industry

With fast product iteration cycles, small batch sizes, high variety, and short lead times becoming the norm, the SK2 linear motor system, combined with rapid automatic tool changing, allows seamless execution of multiple processes in a single setup. From precision kiss-cutting of paperboard, to 3D cutting of foam, to contour cutting and waste removal of adhesive materials, the SK2 delivers speed without compromising quality, even under urgent order pressure.

IECHO SK2 is more than just a machine; it represents a future-oriented production paradigm. Through fundamental technological innovation, it resolves the long-standing trade-offs between precision, speed, and maintainability in manufacturing. For enterprises committed to industrial upgrading and building intelligent, flexible production lines, the SK2 delivers a stable and reliable core foundation for operations.

Post time: Jan-09-2026