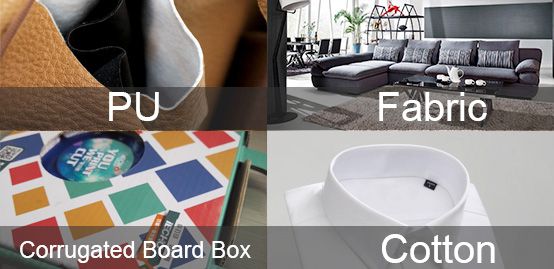

BK2 High Speed Digital Cutting System

feature

application

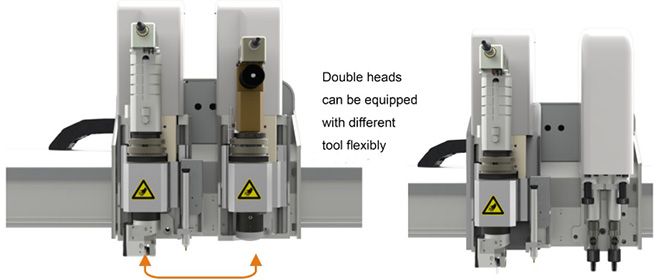

BK2 cutting system is a high speed (single layer/few layers) material cutting system, which is widely applied in automobile interior, advertisement, garment, furniture, and composite materials. It can be precisely used for full cutting, half cutting, engraving, creasing, grooving. This Cutting system provides best choice for many different industries with high efficiency and flexibility.

system

Effective cooling system

The heat sinking device are added to the circuit board, which effectively speed up the heat dissipation in the control box. Compared with the fan heat dissipation, it can effectively reduce the entry of dust by 85%-90%.

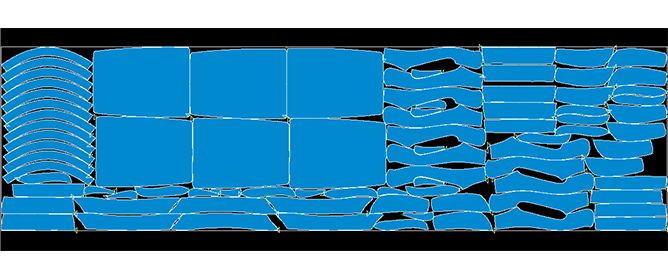

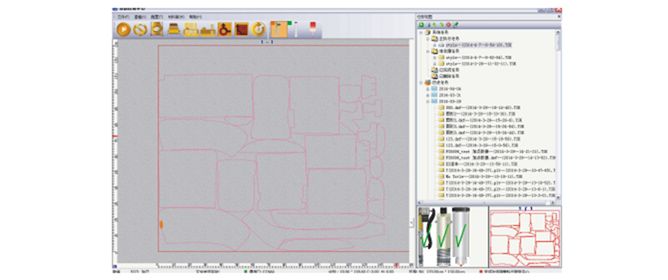

IECHO super automatic nesting system

According to the customized nesting samples and width control parameters which set by customers, this machine can automatically and efficiently generate to the best nesting.

IECHO motion control system

IECHO CutterServer cutting control center enables the cutting process smoother and the cutting result perfect.

Safety device

Safety device ensures the safety of operator while controlling the machine under the high speed processing.