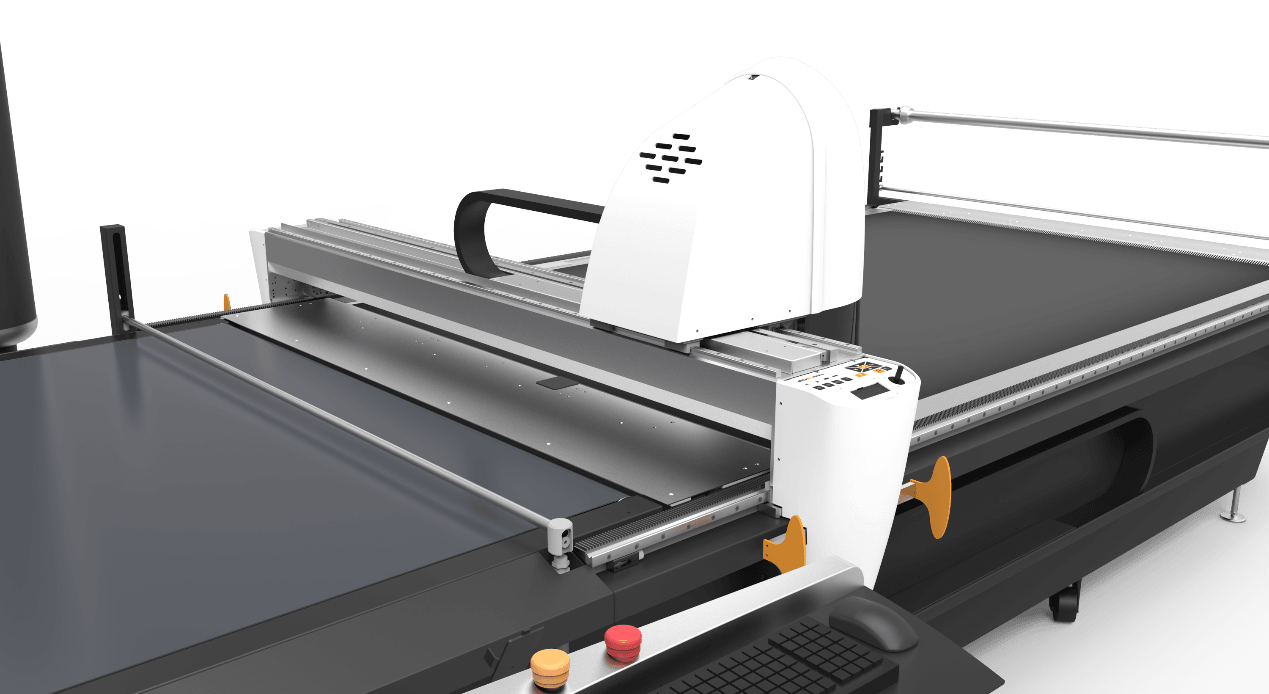

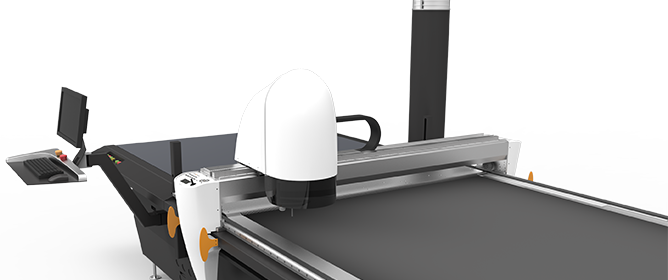

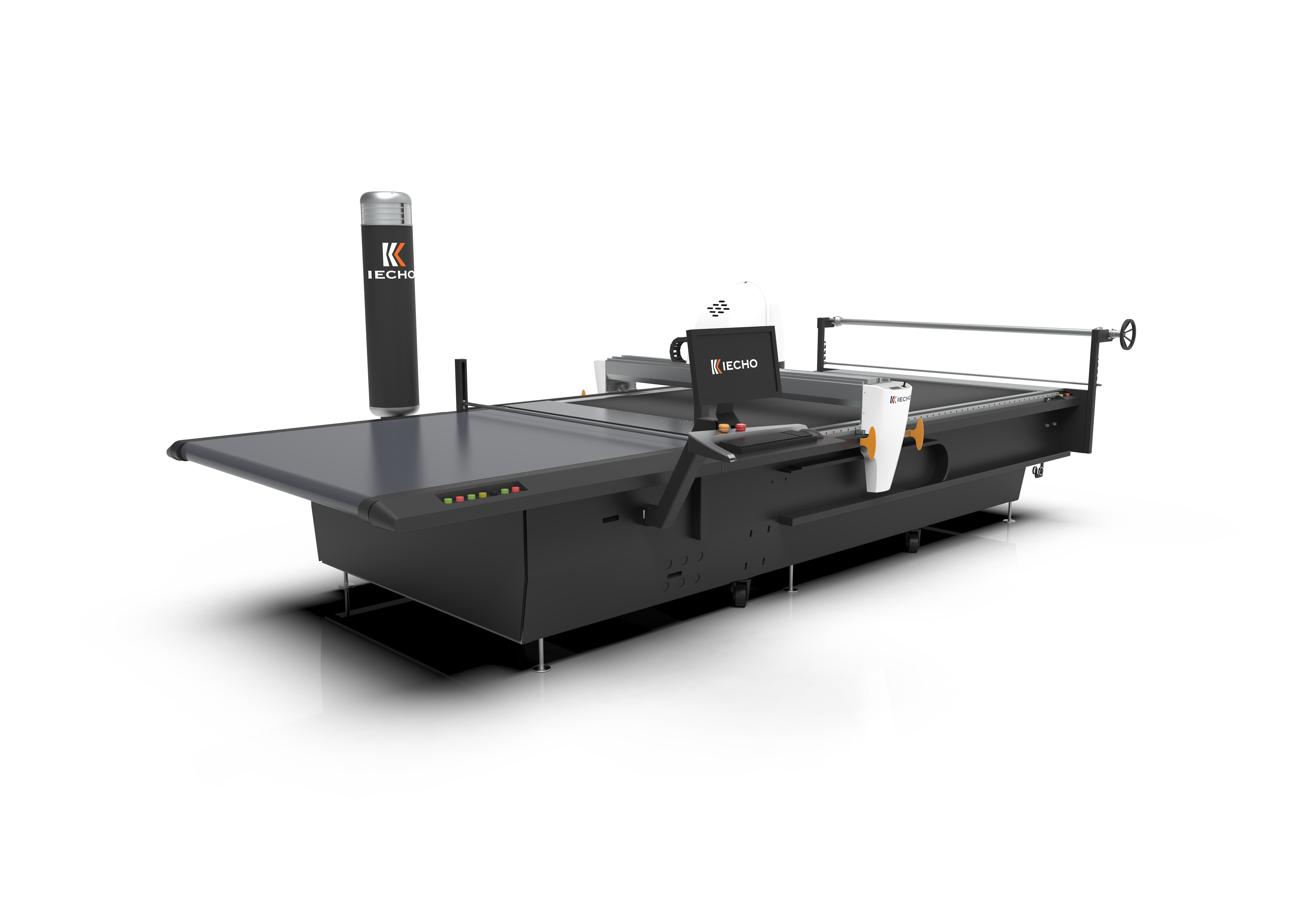

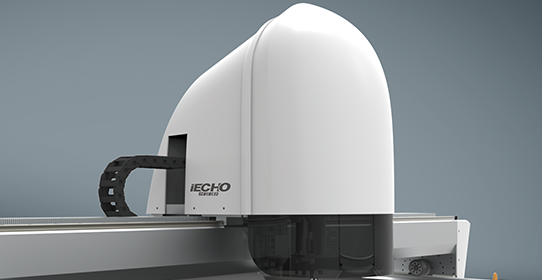

GLSA Automatic Multi-Layer Cutting System

feature

application

GLSA Automatic Multi-Ply Cutting System provides the best solutions for mass production in Textile,Furniture,Car interior, Luggage, Outdoor industries, etc. Equipped with IECHO high speed Electronic Oscillating Tool (EOT), GLS can cut soft materials with high speed,high precision and high intelligence. IECHO CUTSERVER Cloud Control Center has powerful data conversion module, which ensures GLS work with the mainstream CAD software in the market.

parameter

| Max Thickness | Max 75mm(With Vacuum Adsorption) |

| Max Speed | 500mm/s |

| Max Acceleration | 0.3G |

| Work Width | 1.6m/ 2.0mi 2.2m (Customizable ) |

| Work Length | 1.8m/ 2.5m (Customizable) |

| Cutter Power | Single Phase 220V, 50HZ, 4KW |

| Pump Power | Three Phase 380V, 50HZ, 20KW |

| Average Power Consumption | <15Kw |

| lnferface | Serial Port |

| Work Environment | Temperature 0-40°C Humidity 20%-80%RH |

system

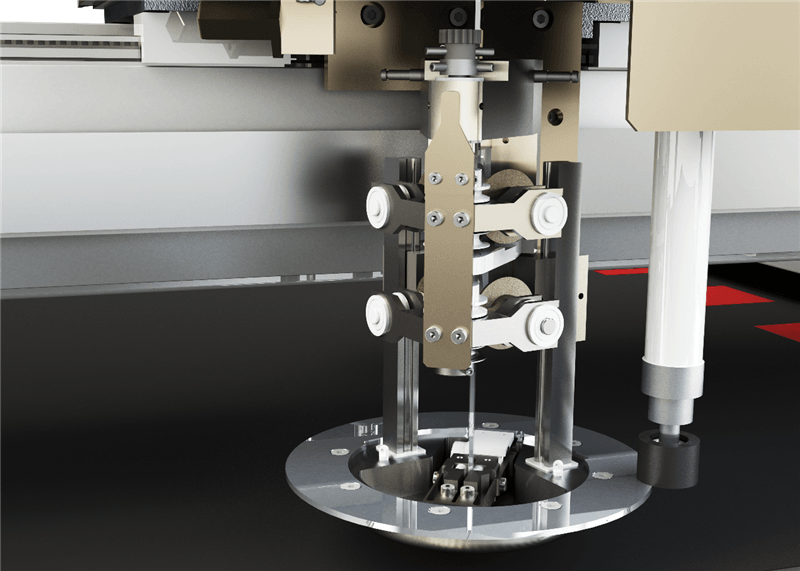

Knife intelligent correction system

Adjust cutting mode according to material difference.

Pump frequency control system

Automatically adjust the suction force, saving energy.

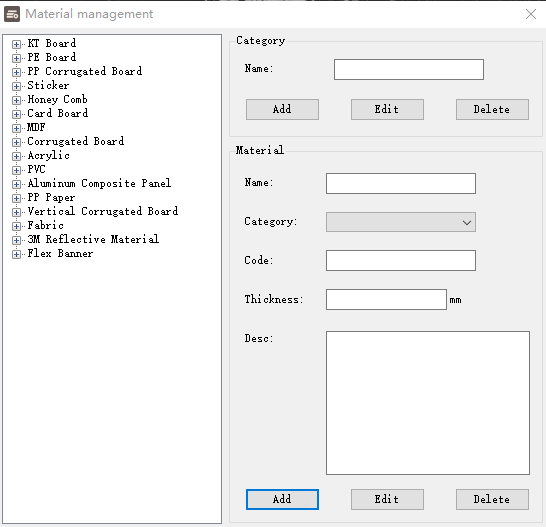

CUTTER SERVER cutting control system

Self-developed easy to operate; providing perfect smooth cutting.

Knife cooling system

Reduce tool heat to avoiding material adhesion.

Intelligent fault detection system

Automatically inspect the operation of cutting machines, and upload data to cloud storage for the technicians to check problems.