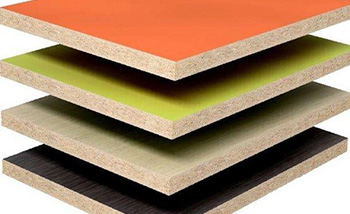

MDF, a medium -density fiber board, is a common wood composite material, is widely used in furniture, architectural decoration and other fields. It consists of cellulose fiber and glue agent, with uniform density and smooth surfaces, suitable for various processing and cutting methods. In modern manufacturing, digital cutting is becoming an important way of processing. Let’s take a look at the characteristics of MDF materials and the advantages of digital cutting.

MDF materials have the following characteristics:

First, the density is uniform and there is no obvious texture difference to make it more stable during processing.

The s is uniform density without significant texture differences, making it more stable during the processing.

Thirdly, MDF are easy to process, and various complex shapes and patterns can be achieved by cutting, hollowing out, carving and other methods. These features provide a good foundation for digital cutting.

As an advanced processing method, digital cutting has many advantages. Firstly, it is high precision and efficiency. Digital cutting can achieve precise cutting of MDF by controlling cutting equipment through computer programs, ensuring product quality and consistency. At the same time, digital cutting has a fast speed, greatly improving production efficiency and saving time and costs.

Secondly, digital cutting has flexibility and diversity. Depending on different design needs, various shapes and sizes can be achieved by adjusting the cutting parameters. This flexibility makes the production process more free and meets the needs of personalized customization.

TK4S Large format cutting system

In addition, digital cutting also has the characteristics of sustainable development. Because the cutting size can be accurately controlled, the waste is reduced, and the material utilization rate is improved. At the same time, digital cutting can also reduce the participation of manual operations, reduce labor intensity, and improve the safety of the working environment.

IECHO RZ The router operates at speeds up to 60000 RPM

In summary, the digital cutting of MDF is of great significance in modern manufacturing. Its characteristics and advantages have made it an important tool for high -quality, high efficiency, and personalized production. With the continuous progress and deepening of technology, digital cutting will be widely used in various industries, bringing more convenience and innovation to our lives.

Post time: Dec-15-2023