Recently, IECHO has conducted a training on the common problems and solutions of LCT and DARWIN laser die-cutting system.

Problems and Solutions of LCT laser die-cutting system.

Recently, some customers have reported that during the cutting process, the LCT laser die-cutting machine is prone to the problem of the bottom paper burning at the starting point.After investigation and analysis by the R&D team of IECHO, the main reasons for these problems are as follows:

1.Customer parameter debugging is incorrect

2.Material property

3.The starting point power setting is too high

At present, these problems have been effectively resolved.

solution:

1.Software optimization starting point function

2.Optimization of waste-cleaning Mechanism

The launch of the new generation LCT laser die-cutting machine

In the second half of this year, IECHO will launch a new generation of LCT laser die-cutting machine. The new model will undergo many software updates to improve production efficiency and accuracy. At the same time, many optional accessories will also be added to the hardware, including the update of the waste structure to meet more special production needs.

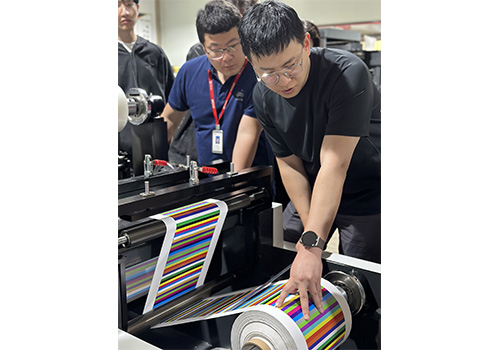

The training and function introduction of DARWIN laser die-cutting system

In addition to the LCT laser cutting machine, IECHO also organized training on DARWIN laser die-cutting system . At present, Darwin has been updated to the second generation, and the third generation will be launched in the second half of the year.

Darwin is designed for small batch production, personalized customization, and orders that need to be delivered quickly to solve the delivery pressure of enterprises,which can reach 2000/h.Through the 3D INDENT technology independently developed by IECHO, the creasing lines can be directly printed on film, and the production process of digital cutting die only takes 15 minutes, which can be made simultaneously during the printing process.Through the Feeder system, the paper passes through the digital creasing area, and after completing the creasing process, it directly enters the laser module unit.

The I Laser CAD software developed by IECHO and the coordinated with high -power laser and high -precision optical instruments to accurately and quickly complete the cutting of the box shapes. This not only improves production efficiency, but also handles various complex cutting shapes on the same equipment. This enables the customer’s diversified needs to meet its requirements more flexible and quickly.

In short, this training provides customers with a way to solve the problem and provides new ideas for the efficient and facilitation of production. IECHO will continue to launch more innovative products and services in the future, bringing more convenience and value to the post-press processing industry.

Post time: May-17-2024