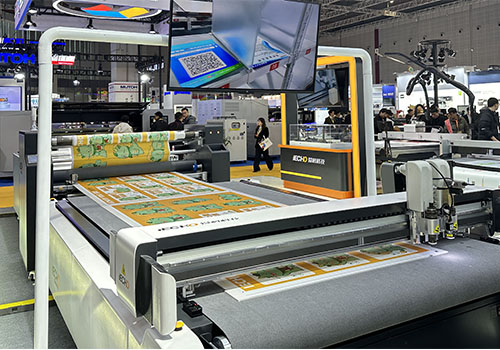

IECHO roll feeding device plays a very important role in the cutting of roll materials, which can achieve maximum automation and improve production efficiency. By equipped with this device, the flatbed cutter can be more efficient in most cases than cutting several layers simultaneously, saving the time of spreading material layer by layer manually.

With the rapid development of the cutting industry, automated production has become an important means to improve production efficiency and reduce costs. Among them, roll feeding device is an important process, and traditional cutting methods often require manual layer by layer manually, which is inefficient and prone to errors. In order to solve this problem, the roll feeding device has appeared, providing a new solution for roll cutting.

The roll feeding device is a highly automated device that can accurately feed materials into the cutting area during the cutting process, ensuring the flatness of the cutting and thus ensuring high-precision cutting. This device adopts advanced control technology, which can accurately control the feeding speed and position, greatly improving the accuracy and efficiency of cutting.

Compared with traditional cutting methods, the roll feeding device has the following significant advantages:

1. High degree of automation: This device can achieve fully automatic feeding, without manual intervention, which greatly reduces labor costs.

2. Improve production efficiency: Due to the reduction of manual laying time, this device is generally more efficient than cutting multiple layers simultaneously.

3. Reduce errors: Due to the smooth feeding, the cutting accuracy has been greatly improved, reducing the rate of waste.

4. Cost saving: By reducing waste of raw materials, enterprises can produce higher quality products at lower costs.

With the continuous development of automated production technology, the market demand for roll feeding devices is constantly increasing. It is expected that in the years, this field will usher in more technological innovation and product upgrades. For cutters, choosing the appropriate roll feeding device will help improve production efficiency, reduce costs, and thus gain an advantage in fierce market competition.

Post time: Mar-13-2024