As demand for personalization continues to rise and market competition intensifies, the apparel manufacturing industry is facing multiple challenges: improving efficiency, reducing costs, and speed up product development. Among all production processes, cutting is one of the most critical stages in garment production, playing a decisive role in overall productivity and product quality. Traditional cutting methods are no longer sufficient for modern manufacturing needs, driving the rapid adoption of automated and intelligent cutting technologies.

At present, the most common automatic fabric cutting equipment on the market fall into three main categories: digital cutting systems, laser cutting machines, and straight-knife cutting machines. Each technology serves different production scales and operational requirements.

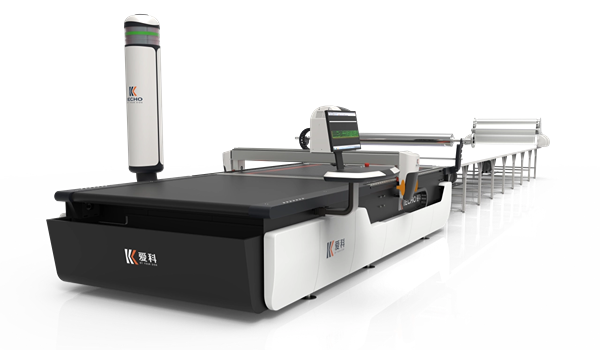

Among them, digital cutting systems are becoming the preferred choice for mid- to high-end, large-scale garment production due to their outstanding accuracy, efficiency, and material utilization. Industry-leading solutions such as the IECHO digital cutting system represent the forefront of intelligent cutting technology.

Intelligent CNC Control Sets New Cutting Standards

IECHO digital cutting machines use high-performance mechanical blades, driven entirely by an intelligent CNC system. From fully automatic loading and unloading to fully automatic cutting, they achieve a complete end-to-end automated workflow. Their core advantages include:

Ultra-high precision and efficiency

An intelligent error-compensation system ensures cutting accuracy of up to ±0.01 mm. Combined with a high-speed motion control system, the machine delivers smooth, seamless cutting of both straight lines and curves, with clean edges; significantly improving both cutting quality and speed.

Revolutionary material savings

The system integrates a super fully automatic intelligent nesting function, capable of optimally arranging both regular and irregular fabric shapes. Proven in practice, it can save multiple times more material on average compared to traditional manual nesting, dramatically reducing production costs.

Ease of use and reduced labor dependence

With computer-aided nesting, employees with basic computer skills can quickly master the system, greatly lowering training costs. Fully automated cutting replaces extensive manual labor, enabling stable, high-quality, large-scale production.

Where Other Cutting Technologies Fall Short

Laser garment cutting machines

Using CO₂ laser tubes for thermal cutting, these machines offer acceptable precision. However, the cutting process generates smoke, odors, and fabric edge scorching, which can negatively affect the working environment and certain fabric types. Overall cutting efficiency is generally lower than that of digital cutting machines.

Straight-knife garment cutting machines

As traditional multi-layer cutting equipment, they require manual fabric spreading and handheld operation. This results in high labor intensity and potential safety risks, while cutting precision and consistency cannot match those of fully automated CNC equipment. They are better suited for small-batch production with high flexibility requirements.

Why Digital Cutting Matters for Modern Apparel Manufacturing

Lower costs, higher efficiency

Automation reduces reliance on skilled cutters, shortens production cycles, and ensures on-time delivery; giving companies a competitive edge in the market.

Consistent, high-quality output

Computer-controlled precision cutting ensures consistency for every pattern piece, fundamentally improving the overall quality of finished garments.

Flexible production capability

Digital cutting systems adapt quickly to order changes, supporting small-batch, multi-style production models.

Sustainable manufacturing

Optimized nesting reduces material waste, aligning with the industry’s sustainable development trends.

As an innovator in intelligent cutting solutions, IECHO is dedicated to supporting garment manufacturers worldwide with advanced digital cutting technology. By embracing intelligent cutting, manufacturers can streamline operations, unlock new growth opportunities, and stay competitive in an evolving global market.

Post time: Dec-24-2025