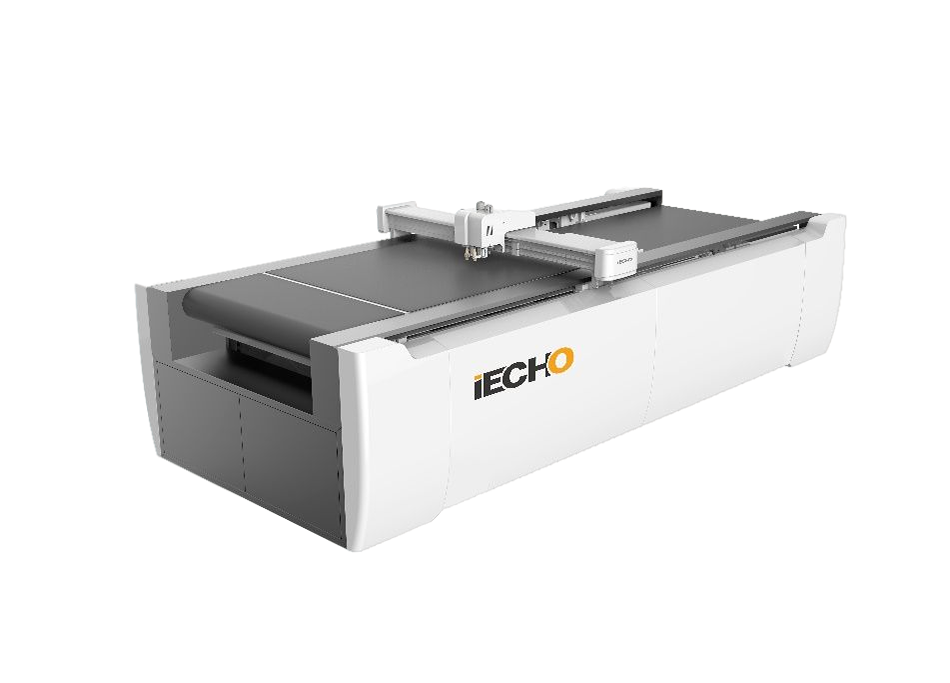

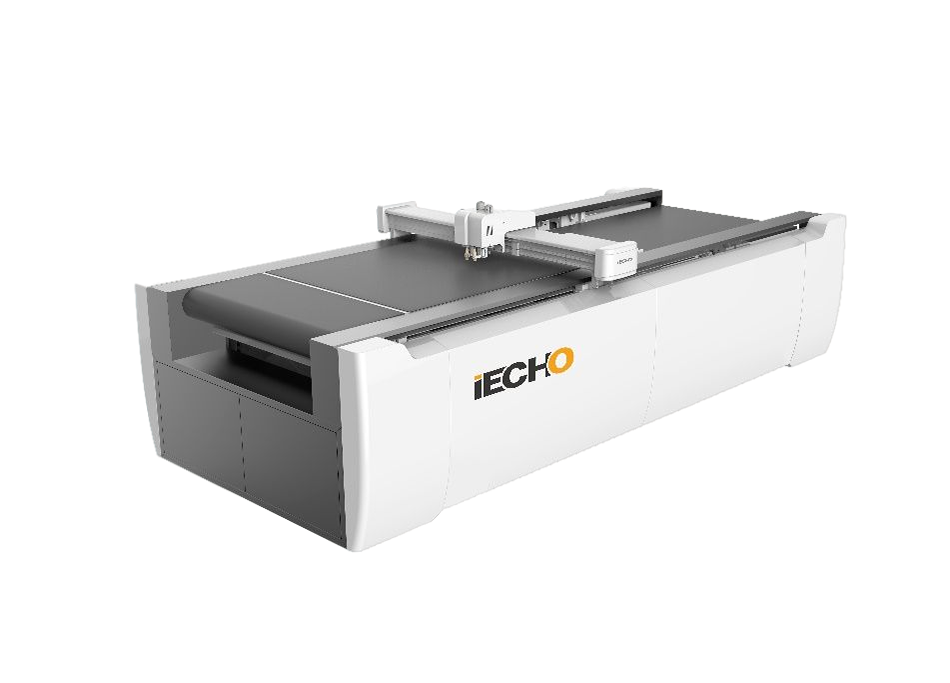

PK1209 automatic intelligent cutting system

feature

application

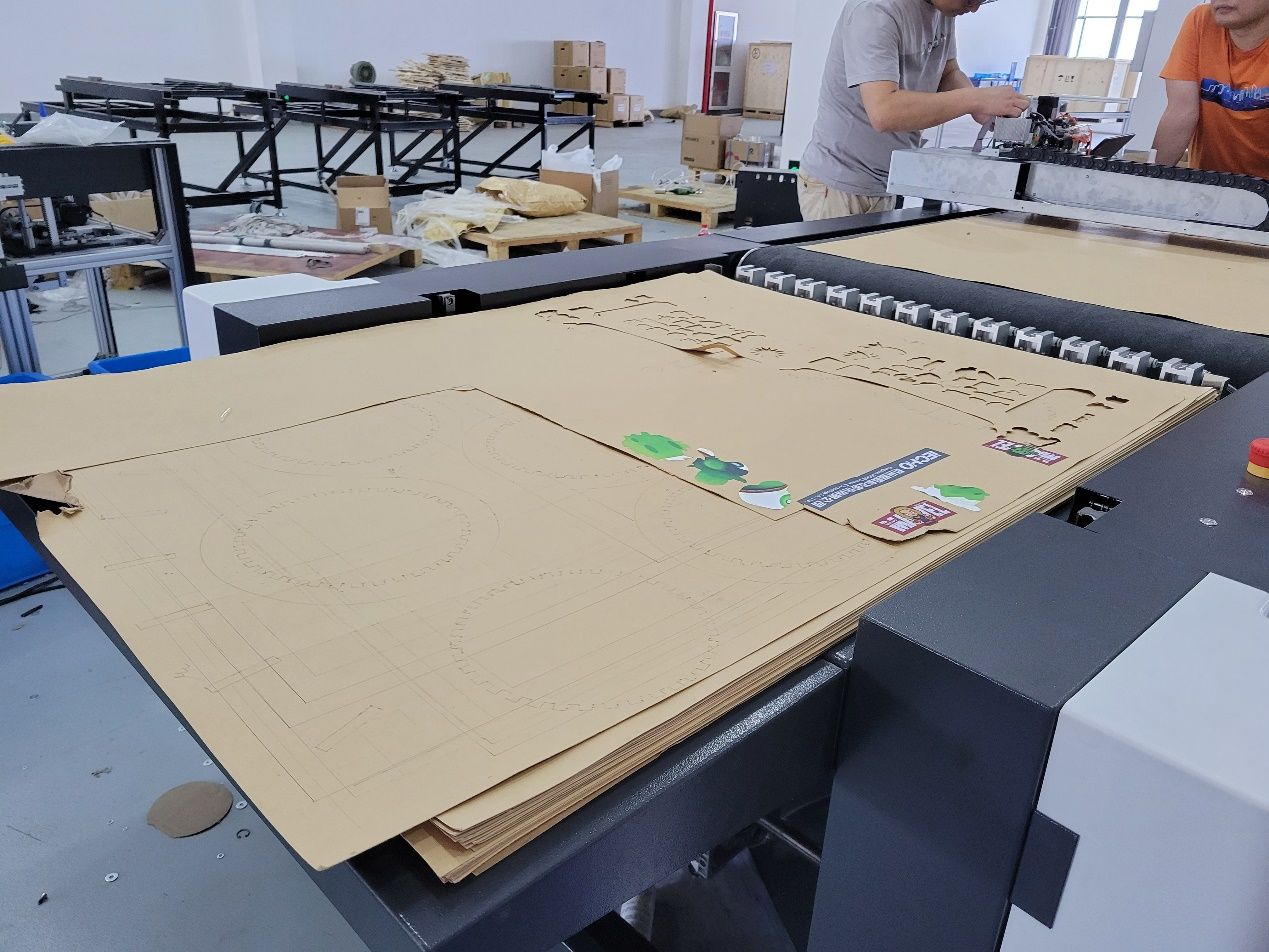

PK automatic intelligent cutting system adopts fully automatic vacuum chuck and automatic lifting and feeding platform. Equipped with various of tools, it can quickly and precisely make through cutting, half cutting, creasing and marking. It is suitable for sample making and short-run customized production for Signs, printing and Packaging industries. It is a cost-effective smart equipment that meets all your creative processing.

parameter

| Cutting Head Type | PKPro Max |

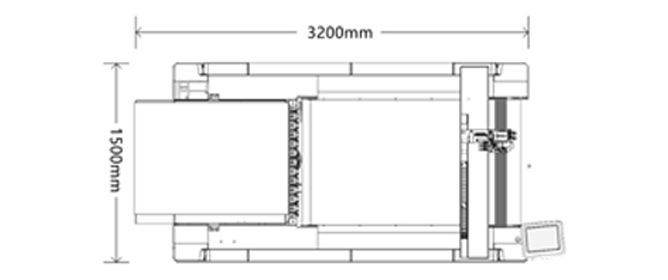

| Machine Type | PK1209 Pro Max |

| Cutting Area(L*W) | 1200mmx900mm |

| Flooring Area(L*WH) | 3200mm×1 500mm×11 50mm |

| Cutting TOOL | Oscillating tool, Universal Cutting Tool, Creasing Wheel, Kiss cut tool, Drag knife |

| Cutting Material | KT Board, PP Paper, Foam Board, Sticker, reflective material, Card Board, Plastic Sheet, Corrugated Board, Grey Board, Corrugated Plastic, ABS Board, Magnetic Sticker |

| Cutting Thickness | ≤10mm |

| Media | Vacuum System |

| Max Cutting Speed | 1500mm/s |

| Cutting Accuracy | ±0.1mm |

| Data Format | PLT、DXF、HPGL、PDF、EPS |

| Voltage | 220v±10%50Hz |

| Power | 6.5kw |

system

Roll materials feeding system

The roll materials feeding system adds the additional value to PK models, which can not only cut sheet materials, but also roll materials such as vinyls to makes labels and tags products, maximizing customers’ profits by using IECHO PK.

Automatic sheet loading system

Automatic sheets loading system suitable for printed materials automatic processing in short run production.

QR code scanning system

IECHO software supports QR code scanning to retrieve relevant cutting files saved in the computer to conduct cutting tasks, which meets the customers’ requirements for cutting different types of materials and patterns automatically and continuously, saving human labor and time.

High precision vision registration system (CCD)

With high definition CCD camera, it can make automatic and accurate registration contour cutting of various printed materials, to avoid manual positioning and printing error, for simple and accurate cutting. Multiple positioning method can meet different materials processing demands, to fully guarantee the cutting accuracy.