Due to the limitations of cutting principles and mechanical structures, digital blade cutting equipment often has low efficiency in handling small-series orders at the current stage, long production cycles, and cannot meet the needs of some complex structured products for small-series orders.

Characteristics of small-series orders:

Small quantity: The quantity of small-series orders is relatively small, mainly small -scale production.

High flexibility: Customers usually have high demand for personalization or customization of products.

Short delivery time: Although the order volume is small and customers have strict requirements for delivery time.

At present, the limitations of traditional digital cutting include low efficiency, long production cycles, and inability to meet the needs of complex structural products. Especially for orders with a number of 500-2000 and this digital production field is facing gap. Therefore, it is necessary to introduce a more flexible, efficient and personalized cutting solution ,which is laser die-cutting system.

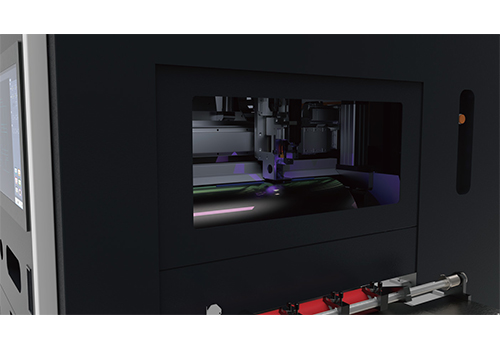

Laser cutting system is a device that uses laser technology. It uses high -energy laser beams to accurately cut materials, which can be suitable for various types of materials.

The working principle of a laser die-cutting machine is to generate a high-energy laser beam through a laser light source, and then focus the laser on a very small spot through an optical system. The interaction between high-energy density light spots and materials leads to local heating, melting, or gasification of the material, ultimately achieving cutting of the material.

Laser cutting solves the maximum speed bottleneck of blade cutting and can complete a large number of complex cutting tasks in a short time, improving production efficiency and capacity.

After solving the speed problem, the next step is to use the digital creasing instead of the traditional processing. When the laser system and innovative digital creasing technology, the last barrier of digital production in the packaging printing industry is broken.

Using 3D INDENT technology to quickly print crease film and the production only takes 15 minutes.There is no need for experienced mold making personnel, just import electronic data into the system, and the system can automatically start printing the mold.

The IECHO Darwin laser die-cutting system has thoroughly farewell to the problems of low efficiency, long production cycle, and high waste rate. At the same time, it has entered the stage of intelligence, automation, and personalization.

Post time: Apr-19-2024